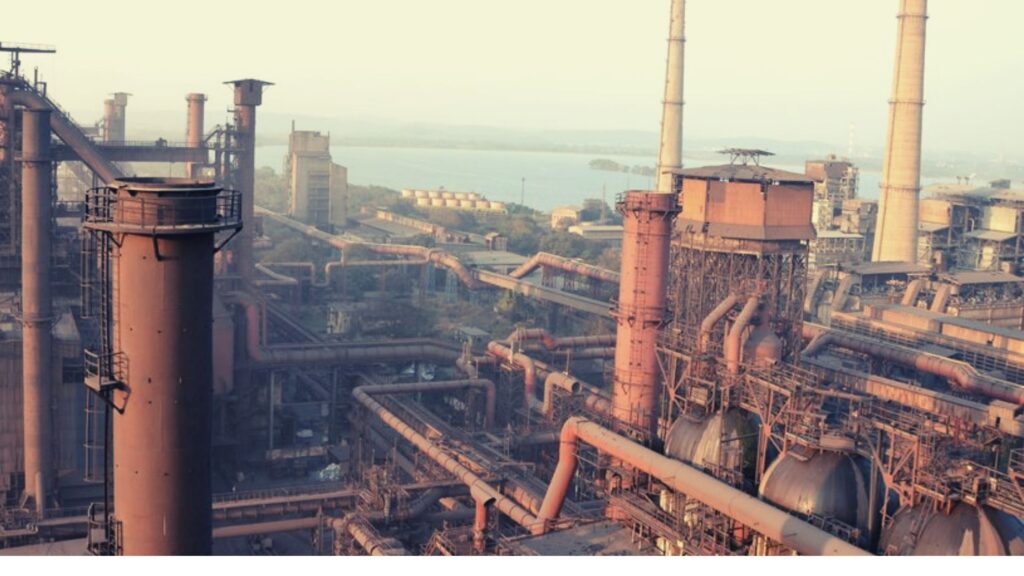

Largest Steel Plants in India – Iron steel industry is the mother of all other industries in the world.The history of iron and steel industry in India is not very old.

It began in India in the last decades of the 19th century. Currently, India is the fourth steel producer in the world.

The first iron industry factory in India was established in 1874 in Kulti (Asansol, West Bengal) in the name of Bengal Iron Works (BIW) .

Later this company was closed in the price of fund and the Bengal government took over it.

Iron and iron minerals, manganese, limestone, fuel (coking coal) and agnis soil are essential for iron and steel industry.

These plants consume large quantities of coal and iron and minerals. As a result, these plants are located either near coal mines or iron-ore deposits.

Raw materials required for iron and steel production (coal, iron ore, water, bauxite, dolomite, etc.) are found in the Chotanagpur plateau.

Bihar, Chhattisgarh, Jharkhand, Karnataka, Madhya Pradesh, Odisha, Tamil Nadu, and West Bengal are the richest in terms of raw materials required for smelting of iron ore.

If we talk about Iron and steel plants in India. There are 12 main iron and steel plants in India.

Except for Tisco, all the major unified plants fall under the public sector. All steel plants under the public sector are supervised by the Steel Authority of India (SAIL).

Following is a brief description of major steel plants in India:-

Largest Steel Plants in India

1. Tata Iron and Steel Company (Jamshevpur)

Tata iron-steel is located very close to the Mumbai-Kolkata railway route. The nearest port for export of steel here (about 240 km away) is Kolkata.

It is located in the Singhbhum district of Jharkhand towards the northwest. TATA Steel is the Global Steel manufacturing company worldwide.

It is the oldest and largest steel company in India. TATA Steel is operated and run by the TATA group, the large business group in India.

Currently, Tata ‘Iron and Steel Company’ (TISCO) and ‘Indian Iron and Steel Company’ (Isco) are working in the private sector in India. TISCOis counted as the largest steel factory in the country.

It was founded in 1907; The plant produced cast iron in 1908 and started making steel in 1911.

One of the biggest plants of TISCO is in Jamshedpur. It is a place where transport expenditure is very less. The company’s corporate office is situated in Mumbai.

The TISCO gets Iron ore as raw material from Badam Pahad (Mayurbhanj-Orissa) and Nawamandi (Singhbhum, Jharkhand), Coking Coal from Jharia, and Bokaro, Manganese from Keonjhar (Orissa), Limestone and Agnisah clay (fire clay) comes from Sundergarh district (Jharkhand), and sweet water is received from Subarnarekha and Kharkai rivers.

Being located in a tribal area, labor is available here at a cheap rate and the finished goods of this plant are exported by Kolkata Port. The TISCO plant has a production capacity of four lakh tons.

The company receives the port facility in the form of Kolkata. While Bihar and Eastern Uttar Pradesh are the areas from where the company gets cheap labor.

The company receives the port facility in the form of Kolkata. While Bihar and Eastern Uttar Pradesh are the areas from where the company gets cheap labor.

2. Steel Authority of India (SAIL)

Steel Authority of India Limited commonly known as SAIL, is a sizable steel company in India. The company was incorporated in 1954. Its head office is situated in New Delhi.

It is the largest steel producing company in India. The company produces both basic and special steel for domestic construction, engineering, power, railway, motor vehicle and safety industries and for sale in the export market.

It is a wholly-owned authority of the Government of India. It is one of the 10 largest public sector companies in the country by trade.

SAIL produces and sells a wide range of steel goods. These include hot, and cold rolled sheets and coils, zinc climbing sheets, electrical sheets, structures, railway products, plate bars and rods, stainless steel, and other alloy steel.

SAIL produces iron and steel at its five integrated steel factories and three specialized steel factories.

These factories are located in the country’s eastern and central regions, and they are the domestic sources of raw materials for the company.

SAIL manufactures durable steel, which is preferred by most of the people in India. The company is recognized for being the second-largest iron ore producer in India.

Indian Iron and Steel Company (Indian Iron and Steel Company / IISCO ) Steel Authority of India Ltd ( SAIL is wholly owned subsidiary of the sector).

There was a time when the name ‘Isco’ was quoted on the London Stock Exchange which was a matter of pride for the Kolkata Stock Exchange in the early 1960s. It was also mentioned in Finance and Industrial Construction (BIFR) in 1949.

Its three units were Kulti, Hirapur, Burnpur. All three factories are connected by railways.

Kulti is situated on the Barakar River and is 215 km from Kolkata. Hirapur is 6 km from Asansol and Kulti is 11 km. Cast iron is made in Hirapur which is manufactured in the kulti factory.

Indian Iron and Steel Company (IISCO) was established in 1918 and the Steel Corporation of Bengal was established in 1952.

Both companies got merged in 1952. After the merger, the company became recognized as IISCO.

It has three plants – Burnpur (5 km south-west of Asansol), Hirapur (about 6 km south of Asansol), and Kulti (about 6 km west of Asansol). In 1972-73, steel production from Indian iron and steel factories was reduced and the plant was acquired by the government.

These steel plants get iron-ore from Goa, coal from Jharia Kau Ramnagar mines, manganese from Bihar, Jharkhand, Madhya Pradesh and Odisha and fire clay from Singhbhum.

Apart from this, electricity at cheap rates is obtained from Damodar Bailey Corporation (DVC) and water from Damodar River. Here, labor is obtained from the Adiyasi region and Bihar at a cheap rate.

The finished products of these plants are exported from Kolkata port.

- Started: 1954

- Corporate Office: New Delhi

3. Visvesvaraya Iron and Steel Plant (VISL)

The third integrated steel plant — Visvesvaiya Iron and Steel Works — initially known as the Mysore Iron and Steel Works, is located near the iron-ore fields of Cayman Gundi in the Babubudan hills.

Visvesvaraya Iron and Steel Plant is located at Bhadravati, formerly known as Mysore Iron and Steel Limited, and was established in 1823. The plant was acquired by the Central Government in 1962.

For the production of iron and steel, metals like Limestone, manganese, dolomite, and fire clay are also available from nearby areas. But coal is not available in this state.

The ore of this plant is obtained from Baba Budan Hill (Chikmagalur District, Karnataka). The plant gets electricity from Jog and Sharawati power projects.

4. Bhilai Iron and Steel Plant (SAIL)

In 1955, an agreement was reached between the former Soviet Union and the Government of India to establish a steel plant in Bhilai, and from the year 1959, the plant started production.

The plant was established in the Durg district of Chhattisgarh in the year 1956 in collaboration with Russia.

The plant has iron ore from Dalli Rajhara mine, coal from Korba (Chhattisgarh), Bokaro, Jharia (Jharkhand), and manganese Balaghat and Bhandara, limestone from Nandini mine, water from Tandula canal and reservoir, and power from Korba thermal power plant.

Since this plant is located in Chhattisgarh’s tribal area, labor is available here at a cheap rate. Ready goods are exported from the Visakhapatnam port.

5. Rourkela Iron and Steel Plant (SAIL)

The Rourkela Steel Plant was established in 1959 in the Sundargarh district of Odisha in collaboration with Germany.

The plant was set up based on the proximity of raw materials, thus reducing the transport value of the weight-loss of raw materials.

The plant has specific locational benefits as it receives coal from nearby Jharia (Jharkhand) and iron ore from Sundergarh and Kendujhar. Electric power for electric furnaces is obtained from the Hirakud Project and water from the ‘Koil and Conch Rivers.

The company is a subsidiary company of Hindustan Steel Limited – HSL. The Workers for the company are easily available from Jharkhand and Bihar at lower wages.

6. Durgapur Iron and Steel Plant (HSL)

Durgapur Steel Plant Government of United Kingdom Cooperation was established in West Bengal and started production in 1962. The Durgapur Iron and Steel Plant was established in 1956 with the help of Britain.

The plant is located in Raniganj and Jharia coal belt and iron ore is obtained from Noamandi (map).

Durgapur is located on the Kolkata-Delhi railway route near the banks of the Damodar River. It receives hydroelectric power and water from Damodar Valley Corporation (DVC).

It receives iron-ore from Singhbhum (Jharkhand), coal from Raniganj, manganese from Balaghat (Madhya Pradesh), and water from Damodar River. The company produces ingot steel.

7. Visakhapatnam Steel Plant

An agreement was reached between India and the Soviet Union in 1979 about this plant.

Finally, the Government of India gave its approval in the year 1982. It has been established near the port of Visakhapatnam. The base of this plant was laid in 1970 but production started in 1992 in this plant.

The plant was established by Rashtriya Ispat Nigam Limited. It is the only plant in India, located in the coastal region. The plant is the first integrated steel plant in the country which has completed ISO Certificate.

The plant derives iron-ore from Bailadila (Chhattisgarh), coal from Bokaro, Raniganj, and Jharia, limestone, and dolomite from Bastar (Chhattisgarh), Madhya Pradesh, and Orissa. The Visakhapatnam plant has a capacity of 2 to 3 lakh tons.

8. Bokaro Steel Plant (SAIL)

In the Third Five-Year Plan period (1961-66) the foundation stone of a new factory was laid at Bokaro, Jharkhand. It is one of Asia’s largest iron steel in India.

The factory was established in Bokaro in 1964 on the banks of the Damodar River in collaboration with the then Soviet Union.

The plant was established on the basis of transport cost reduction principle, according to which ‘Bokaro and Rourkela jointly obtain iron ore from the Rourkela region and in return, the freight coaches carry coal to Rourkela.

Other raw materials are received by Bokaro within a radius of about 350 km. Water and hydroelectric power are supplied by Damodar Valley Corporation.

9. Rashtriya Ispat Nigam Limited (RINL)

Rashtriya Ispat Nigam Limited, commonly known as Vizag steel, is the foremost steel manufacturing company in India.

The company was founded in 1982. Its corporate head office is located in Visakhapatnam. RINL is a Navratna status company that is operated and run by the Government of India under the ministry of steel.

- Started: 1982

- Corporate Office: Visakhapatnam

10. Salem Steel Plant

The steel plant was established in 1982. The plant derives iron-ore, manganese, dolomite, and limestone from adjacent areas.

For the plant, laborers at low wages are easily available and there is also a large market facility for generating huge sales.

What are the Problems of the Iron and Steel Industry

The iron and steel industry in India is facing the following problems:

1. More Investment:- Iron and steel industry requires more capital for setting up. Apart from this, the gestation period of this plant is also longer.

2. Obsolete machinery:- Iron and steel plants set up during the Second Five-Year Plan are not functioning to their full potential. Because these plants Machinery is very old in India. In addition, the industry has been adversely affected by the rising price of coking coal.

3. Public sector:- Iron and steel plants are running into losses due to mismanagement.

4. Controlled Price:- The pricing of iron and steel is done by the government due to which the producer does not get much profit.

5. Small steel plants running at a loss:- Many iron and steel plants are running at a loss due to insufficient power supply and rising raw material costs.

6. Coking coal shortage:- India’s coking coal reserves are mainly confined to the Jharia and Raniganj coal mines. The coal mines of coal have become very deep, and the price of coal has gone up. As a result, the value of energy investment in iron and steel plants has increased.

7. Competition in the international market:- Competition in the international market with Australia, Brazil, France, Germany, Canada, Sweden, Britain, and the United States has increased the problems of this industry even more.

The sequence of development of iron and steel industry in India.

The evolution of iron-steel industries in India dates back to the year 1874 when the ‘Bengal Iron Works’ was established in Kulti, West Bengal. It was later renamed ‘Brakkar Iron Works’ when it was acquired by the Government of Bengal.

PLEASE SEND US THE DETAILS.